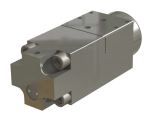

PI73-SS benefits and qualification testing

|

It is recognised that reliability and consistent performance are critical in subsea operations where the cost of failure can be extremely high. The operational benefits which the PI73-SS can provide are significant and attractive (see left hand column below). For this reason, Marshalsea Hydraulics and various client companies have run a number of qualification trials of this innovative product. The trials that have taken place are summarised on the right.

|

External testing (Wormald)8 to 1 ratio intensifier, discharge pressure 1,250 bar mineral oil @ 80 deg C (artificially heated), total number of cycles 4,000. Application: topside high temperature/ pressure wells. Projects: Shearwater/Elgin Frankling/ Sable. Internal testing5 to 1 ratio intensifier, discharge pressure 1,500 bar; water glycol Transaqua HT at 20°C; total number of cycles 174,000. Application: subsea. Internal life test5 to 1 ratio intensifier, discharge pressure 1,500 bar; water glycol Transaqua HT at 20°C; total number of cycles 500,000. Application: subsea, sea water washed. Project: Shell/Cook/Kvaerner. Internal life test5 to 1 ratio Intensifier, discharge pressure 1,000 bar; water glycol Transaqua HT at 20°C; total number of cycles 526,000. Application: subsea. Internal life test2.5 to 1 intensifier, discharge pressure 950 bar; water glycol HW443 at 20°C; total number of cycles 100,000. Application: subsea control module mounted (dual redundant module), Project: Vigdis/Norsk Hydro/FMC Kongsberg. Click for the published conclusions of this test. Internal life test3 to 1 intensifier, discharge pressure 1035 bar; water glycol HW740R at 20°C; total number of cycles 750,000. Application: subsea control module mounted (dual redundant intensifiers). Project: Rhum BP/ABB Offshore. Click for the published conclusions of this test. External testing (READ)8 to 1 down hole intensifier (less than 4 in/100mm in diameter); discharge pressure 22,500 psig of water glycol. Application: subsea swaging of casing tube. |

|||||||||||||||||||||||||||||||||