PI39-TS stainless steel pressure intensifier (topside version)

Designed to boost the pressure of any water-based or mineral/synthetic oil-based fluid. |

||

Boosts inlet pressure up to 5 times without external power. The maximum outlet pressure is 900 bar. |

||

When system pressure is achieved, there is minimal consumption of expensive hydraulic fluid. |

||

External components manufactured from 316 (standard) no painting required for hostile environments. |

|

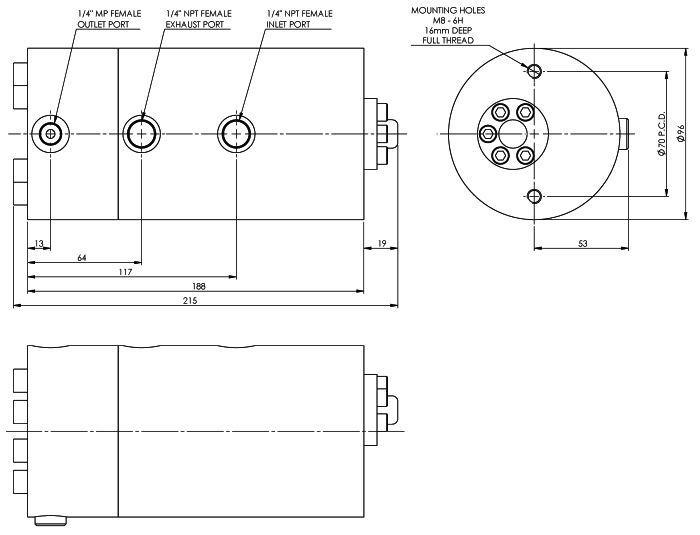

The PI39-TS Intensifier amplifies the inlet pressure to a higher outlet pressure by a predetermined ratio. Pressure in the high pressure line can become reduced as a result of a system leak or the use of the stored (pressure) energy. The PI39-TS restores and maintains that pressure in such instances. Check and changeover valves are integrated within the main body of the intensifier. When the inlet pressure x the ratio = the outlet pressure, then the PI39-TS is in a stalled condition and there is minimal consumption of fluid. The maximum outlet pressure is 900 bar. The PI39-TS does not contain a high pressure line vent valve. ApplicationsThe PI39-TS was designed principally for applications in the offshore oil and gas industry where the highest standards of product performance and durability are essential. The PI39-TS's external components are manufactured from 316 & 17/4 PH stainless steel to withstand hostile environments; it can operate on all water-based glycol fluids or on mineral and synthetic oils. |

MaterialManufactured from stainless steel with nitrile seals as standard. Weight: 11 kgs. FluidsSuitable for use with mineral/synthetic oils and all water-based fluids such as HW443 and Transaqua HT2, plus many others. The fluids used should be to a cleanliness standard of NAS 1638 class 6 or better. MountingThe pressure intensifier can be mounted vertically or horizontally. System temperatureThe PI39-TS has been qualified to operate at temperatures from –10°C to +80°C (Ambient) at pressures up to a maximum of 900 bar. Safety noteThe inlet pressure of the intensifier should be carefully controlled, as the outlet pressure increases by the ratio of the intensifier in use. For example, if an 5:1 intensifier is being used, a rise in the inlet pressure of 100 bar will immediately increase the outlet pressure by 500 bar. A relief valve set at the maximum pump rating should be fitted immediately downstream of the pump delivery port. |

| Intensifier ratio | Maximum Inlet pressure (bar) | Maximum HP output pressure (bar) | Inlet/Exh Port | HP output port | HP swept volume (cc) | Part number |

|---|---|---|---|---|---|---|

| 2:1 | 345 | 690 | 1/4 NPT Female | 1/4" MP Female | 19.5 | PI39-02001-00-01-13-TS-NIT-0345 |

| 2.5:1 | 345 | 862 | 1/4 NPT Female | 1/4" MP Female | 15.6 | PI39-02501-00-01-13-TS-NIT-0345 |

| 3:1 | 300 | 900 | 1/4" NPT Female | 1/4" MP Female | 13 | PI39-03001-00-01-13-TS-NIT-0300 |

| 4:1 | 225 | 900 | 1/4" NPT Female | 1/4" MP Female | 9.75 | PI39-04001-00-01-13-TS-NIT-0225 |

| 5:1 | 180 | 900 | 1/4" NPT Female | 1/4" MP Female | 7.8 | PI39-05001-00-01-13-TS-NIT-0180 |

| PI39 | = Pressure Intensifier 73cc LP piston swept volume | Model | ||||||||||||||

| 02001 | = 2.00:1 | Ratio | ||||||||||||||

| 02501 | = 2.50:1 | |||||||||||||||

| 04001 | = 4.00:1 | |||||||||||||||

| 00 | = No vent Valve | Vent Valve Option | ||||||||||||||

| 01 | = 1/4" NPT Female | Inlet and Exhaust

Ports |

||||||||||||||

| 02 | = 1/4" BSP Female | |||||||||||||||

| Other options available on request | ||||||||||||||||

| 01 | = 1/4" NPT Female | HP Outlet

Connection |

||||||||||||||

| 02 | = 1/4" BSP Female | |||||||||||||||

| 13 | = 1/4" MP Female | |||||||||||||||

| Other options available on request | ||||||||||||||||

| TS | = Topside Installation | Target Location | ||||||||||||||

| NIT | = Nitrile seals -20°C to +80°C | Vent Valve Option | ||||||||||||||

| VIT | = Viton seals -10°C to +80°C | |||||||||||||||

| Other options available on request | ||||||||||||||||

| 0270 | = 270 bar | Maximum Working

Pressure LP Side |

||||||||||||||

| PI39 | - | 02001 | - | 00 | - | 01 | - | 01 | - | TS | - | NIT | - | 0420 | Ordering Example | |