XW WATER/GLYCOL PUMPS

|

|

The high pressure XW type hydraulic pump is suitable for a wide range of fluids including water-based solutions and oil-based fluids. Separation of the lubricating oil and the pumped fluid is achieved by the installation of a cavity between the cylinder block and the case. Bypass from the pistons is collected in this cavity and returned to the inlet side of the pump.

The pump is available with either three or six pistons. The six piston version can be supplied with duplex deliveries which may be used for simultaneous high and low pressure applications when used with an automatic unloading valve. Additional variations are possible by varying the input speed to a maximum of 1,800rpm.

Various combinations of flows and pressures are possible within the 15 kw range up to a maximum of 1040 bar (15,080 psi) and flow rates up to 41.2 l/m (10.8 USg/m) – see table below.

Rotation is bi-directional and the pump may be mounted horizontally or vertically.

A suction filter of 150 microns or better should be used. Finer filtration is desirable for the pump life, but is important that the inlet flowrate to the pump is not restricted and no more than -2 in.Hg is measured in the suction pipework under pumping conditions. Where possible a positive pressure should be maintained in the suction pipework under flowing conditions. When the pump is stationary the suction line should be kept under positive pressure to allow priming.

Important - pumps are delivered from Marshalsea with the case lubricating oil drained. Before the pumps are used, the case should be filled with Castrol Alphasyn PG150 to the level specified on the pump technical data sheet

All externally exposed components are manufactured from 316 stainless steel, except the case which is painted cast steel (Norsok M501 paint system is available). Pump shaft is medium carbon steel EN9 or EN8M.

45 Kg

| Part Number | Cylinders | Flow | Flow @ 1450 RPM | Flow @ 1750 RPM | Pressure | ||

|---|---|---|---|---|---|---|---|

| cc/rev | l/m | Usg/m | l/m | Usg/m | bar | ||

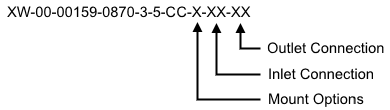

| XW-00-00159-0870-3-5-XX-X-XX-XX | 3 | 1.59 | 2.31 | 0.610 | 2.79 | 0.736 | 870 |

| XW-00-00208-0870-3-5-XX-X-XX-XX | 3 | 2.08 | 3.02 | 0.796 | 3.64 | 0.961 | 870 |

| XW-00-00263-0870-3-5-XX-X-XX-XX | 3 | 2.63 | 3.82 | 1.008 | 4.61 | 1.216 | 870 |

| XW-00-00320-0870-3-6-XX-X-XX-XX | 3 | 3.20 | 4.64 | 1.225 | 5.60 | 1.479 | 870 |

| XW-00-00416-0870-3-6-XX-X-XX-XX | 3 | 4.16 | 6.03 | 1.592 | 7.28 | 1.922 | 870 |

| XW-00-00526-0870-3-6-XX-X-XX-XX | 3 | 5.26 | 7.63 | 2.015 | 9.21 | 2.432 | 870 |

| XW-00-00526-0975-3-6-XX-X-XX-XX | 3 | 5.26 | 7.63 | 2.015 | 9.21 | 2.432 | 975 |

| XW-00-00653-0520-3-6-XX-X-XX-XX | 3 | 6.53 | 9.47 | 2.500 | 11.43 | 3.017 | 520 |

| XW-00-00786-0520-3-6-XX-X-XX-XX | 3 | 7.86 | 11.40 | 3.011 | 13.76 | 3.633 | 520 |

| XW-00-00834-0520-6-6-XX-X-XX-XX | 6 | 8.34 | 12.09 | 3.191 | 14.59 | 3.851 | 520 |

| XW-00-00960-0520-6-4-XX-X-XX-XX | 6 | 9.60 | 13.92 | 3.676 | 16.80 | 4.436 | 520 |

| XW-00-01250-0410-6-4-XX-X-XX-XX | 6 | 12.50 | 18.12 | 4.785 | 21.87 | 5.775 | 410 |

| XW-00-01580-0325-6-4-XX-X-XX-XX | 6 | 15.80 | 22.91 | 6.048 | 27.65 | 7.300 | 325 |

| XW-00-01958-0260-6-4-XX-X-XX-XX | 6 | 19.58 | 28.39 | 7.495 | 34.27 | 9.046 | 260 |

| XW-00-02358-0215-6-4-XX-X-XX-XX | 6 | 23.58 | 34.19 | 9.027 | 41.27 | 10.895 | 215 |

| XW-00-00159-1040-3-5-XX-X-XX-XX | 3 | 1.59 | 2.31 | 0.610 | 2.79 | 0.736 | 1040 |

| XW-00-00208-1040-3-5-XX-X-XX-XX | 3 | 2.08 | 3.02 | 0.796 | 3.64 | 0.961 | 1040 |

| XW-00-00263-1040-3-5-XX-X-XX-XX | 3 | 2.63 | 3.82 | 1.008 | 4.61 | 1.216 | 1040 |

| XW-00-00320-1040-3-6-XX-X-XX-XX | 3 | 3.20 | 4.64 | 1.225 | 5.60 | 1.479 | 1040 |

| XW-00-00416-1040-3-6-XX-X-XX-XX | 3 | 4.16 | 6.03 | 1.592 | 7.28 | 1.922 | 1040 |