XWH WATER/GLYCOL PUMPS

|

|

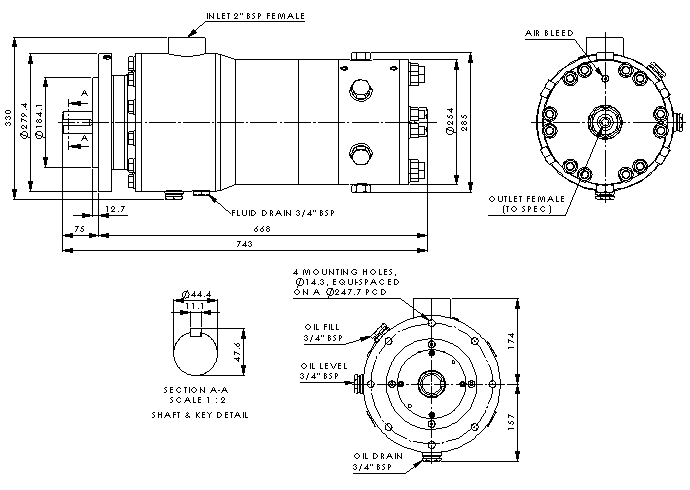

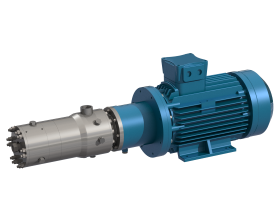

The high pressure 50kW type XWHR1 hydraulic pump is specifically designed for water-based fluids. Separation of the lubricating oil and the pumped fluid is achieved by the installation of a cavity between the cylinder block and the case. Bypass from the pistons is collected in this cavity and returned to the inlet side of the pump. The XWHR1 pump incorporates up to six axial pistons actuated by a single rotating swash plate.

This high powered pump is highly suitable for Blow Out Preventer (BOP) applications, hydraulic power units (HPUs) and flushing skids.

Rotation is bi-directional and the pump may be mounted horizontally or vertically.

A suction filter of 150 microns or better should be used. Finer filtration is desirable for the pump life, but is important that the inlet flowrate to the pump is not restricted. It is recommended on this size of pump, a positive head of at least 0.1 bar is manintained on the suction line under flowing conditions.

Important - pumps are delivered from Marshalsea with the case lubricating oil drained. Before the pumps are used, the case should be filled with the oil specified on the pump technical data sheet

All external components manufactured from 316 stainless steel – pump shaft is medium carbon steel EN9 or EN8.

200 Kg

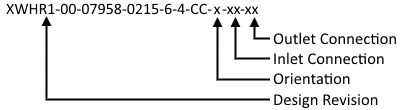

| Part Number | Cylinders | Flow | Flow @ 1450 RPM | Flow @ 1750 RPM | Pressure | ||

|---|---|---|---|---|---|---|---|

| cc/rev | l/m | Usg/m | l/m | Usg/m | bar | ||

| XWHR1-00-01336-0690-3-4-CC-x-xx-xx | 3 | 13.36 | 19.37 | 5.114 | 23.38 | 6.172 | 690 |

| XWHR1-00-01618-0690-3-4-CC-x-xx-xx | 3 | 16.18 | 23.46 | 6.194 | 28.32 | 7.476 | 690 |

| XWHR1-00-01922-0690-3-4-CC-x-xx-xx | 3 | 19.22 | 27.87 | 7.358 | 33.64 | 8.880 | 690 |

| XWHR1-00-02255-0690-3-4-CC-x-xx-xx | 3 | 22.55 | 32.70 | 8.633 | 39.47 | 10.419 | 690 |

| XWHR1-00-02615-0690-3-4-CC-x-xx-xx | 3 | 26.15 | 37.91 | 10.009 | 45.76 | 12.080 | 655 |

| XWHR1-00-03004-0690-3-4-CC-x-xx-xx | 3 | 30.04 | 43.56 | 11.500 | 52.57 | 13.879 | 570 |

| XWHR1-00-03414-0605-3-4-CC-x-xx-xx | 3 | 34.14 | 49.50 | 13.068 | 59.74 | 15.772 | 500 |

| XWHR1-00-03857-0535-3-4-CC-x-xx-xx | 3 | 38.57 | 55.92 | 14.764 | 67.49 | 17.818 | 445 |

| XWHR1-00-04319-0480-3-4-CC-x-xx-xx | 3 | 43.19 | 62.63 | 16.534 | 75.58 | 19.954 | 395 |

| XWHR1-00-04816-0430-3-4-CC-x-xx-xx | 3 | 48.16 | 69.83 | 18.435 | 84.28 | 22.249 | 355 |

| XWHR1-00-05331-0385-3-4-CC-x-xx-xx | 3 | 53.31 | 77.30 | 20.406 | 93.29 | 24.628 | 320 |

| XWHR1-00-02672-0690-6-4-CC-x-xx-xx | 6 | 26.72 | 38.74 | 10.228 | 46.76 | 12.344 | 640 |

| XWHR1-00-03236-0640-6-4-CC-x-xx-xx | 6 | 32.36 | 46.92 | 12.388 | 56.63 | 14.951 | 530 |

| XWHR1-00-03844-0535-6-4-CC-x-xx-xx | 6 | 38.44 | 55.74 | 14.716 | 67.28 | 17.761 | 445 |

| XWHR1-00-04510-0460-6-4-CC-x-xx-xx | 6 | 45.10 | 65.40 | 17.266 | 78.93 | 20.838 | 380 |

| XWHR1-00-05230-0395-6-4-CC-x-xx-xx | 6 | 52.30 | 75.83 | 20.019 | 91.52 | 24.161 | 325 |

| XWHR1-00-06008-0345-6-4-CC-x-xx-xx | 6 | 60.08 | 87.12 | 23.000 | 105.15 | 27.759 | 285 |

| XWHR1-00-06828-0300-6-4-CC-x-xx-xx | 6 | 68.28 | 99.00 | 26.136 | 119.48 | 31.543 | 250 |

| XWHR1-00-07714-0265-6-4-CC-x-xx-xx | 6 | 77.14 | 111.85 | 29.527 | 134.99 | 35.637 | 220 |

| XWHR1-00-08638-0240-6-4-CC-x-xx-xx | 6 | 86.38 | 125.25 | 33.067 | 151.17 | 39.909 | 200 |

| XWHR1-00-09631-0215-6-4-CC-x-xx-xx | 6 | 96.31 | 139.66 | 36.869 | 168.55 | 44.497 | 175 |

| XWHR1-00-10662-0190-6-4-CC-x-xx-xx | 6 | 106.62 | 154.59 | 40.813 | 186.58 | 49.257 | 160 |