LM Oil Pumps

|

|

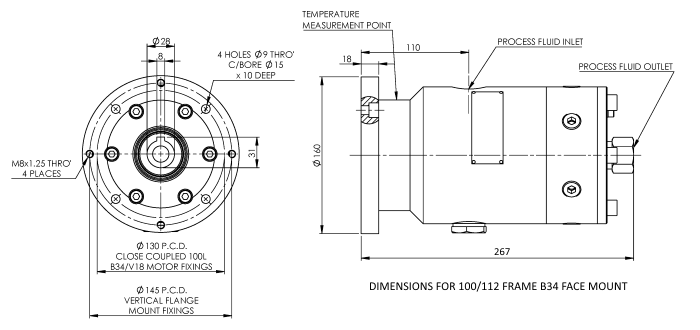

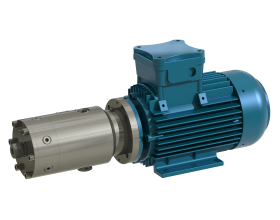

Based on our proven SM pump design, the type LM hydraulic axial piston pump for hydraulic oil application has been specially designed for direct mounting to AC motors, avoiding the need for a bell housing and coupling. A shaft version compatible with a traditional bell housing and coupling is available.

The Type LM hydraulic axial piston pump is of a rotating swash plate design and can deliver pressures up to 690 bar.

To suit your fluid compatibility, environment, maintenance and value requirements, these pumps are available with all 316 stainless steel external components, all carbon steel or a combination of carbon steel with an aluminium case.

The LM pump is available with 3 or 6 pistons, providing flow rates up to 10.60 l/m (2.80 USg/m) as listed in the table below.

These pumps are designed to run on mineral oils with an operating viscocity between 15 and 100 cst. Consult the factory for viscocities outside this range. The ambient operating temperature range is -20°C to +60°C

Rotation is bi-directional and the pump may be mounted horizontally or vertically.

A suction filter of 150 microns or better should be used. Finer filtration is desirable for the pump life, but is important that the inlet flowrate to the pump is not restricted and no more than -2 in.Hg is measured in the suction pipework under pumping conditions. Where possible a positive pressure should be maintained in the suction pipework under flowing conditions. When the pump is stationary the suction line should be kept under positive pressure to allow priming.

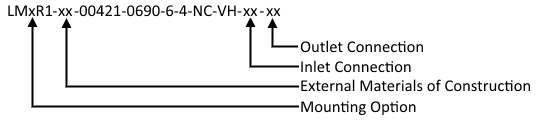

| Part Number | Cylinders | Flow | Flow @ 1450 RPM | Flow @ 1750 RPM | Pressure | ||

|---|---|---|---|---|---|---|---|

| cc/rev | l/m | Usg/m | l/m | Usg/m | bar | ||

| LMxR2-xx-00053-0690-3-4-NC-VH-xx-xx | 3 | 0.53 | 0.76 | 0.201 | 0.92 | 0.243 | 690 |

| LMxR2-xx-00076-0690-3-4-NC-VH-xx-xx | 3 | 0.76 | 1.10 | 0.290 | 1.32 | 0.350 | 690 |

| LMxR2-xx-00103-0690-3-4-NC-VH-xx-xx | 3 | 1.03 | 1.49 | 0.394 | 1.80 | 0.476 | 690 |

| LMxR2-xx-00135-0690-3-4-NC-VH-xx-xx | 3 | 1.35 | 1.95 | 0.515 | 2.35 | 0.622 | 690 |

| LMxR2-xx-00170-0690-3-4-NC-VH-xx-xx | 3 | 1.70 | 2.47 | 0.652 | 2.98 | 0.787 | 690 |

| LMxR2-xx-00210-0690-3-4-NC-VH-xx-xx | 3 | 2.10 | 3.05 | 0.805 | 3.68 | 0.971 | 690 |

| LMxR2-xx-00254-0690-3-4-NC-VH-xx-xx | 3 | 2.54 | 3.69 | 0.974 | 4.45 | 1.175 | 690 |

| LMxR2-xx-00303-0690-3-4-NC-VH-xx-xx | 3 | 3.03 | 4.39 | 1.159 | 5.30 | 1.399 | 690 |

| LMxR2-xx-00505-0610-3-4-NC-VH-xx-xx | 3 | 5.05 | 7.32 | 1.934 | 8.84 | 2.334 | 610 |

| LMxR2-xx-00105-0690-6-4-NC-VH-xx-xx | 6 | 1.05 | 1.52 | 0.402 | 1.84 | 0.486 | 690 |

| LMxR2-xx-00151-0690-6-4-NC-VH-xx-xx | 6 | 1.51 | 2.20 | 0.580 | 2.65 | 0.699 | 690 |

| LMxR2-xx-00206-0690-6-4-NC-VH-xx-xx | 6 | 2.06 | 2.99 | 0.789 | 3.61 | 0.952 | 690 |

| LMxR2-xx-00269-0690-6-4-NC-VH-xx-xx | 6 | 2.69 | 3.90 | 1.030 | 4.71 | 1.243 | 690 |

| LMxR2-xx-00341-0690-6-4-NC-VH-xx-xx | 6 | 3.41 | 4.94 | 1.304 | 5.96 | 1.574 | 690 |

| LMxR2-xx-00421-0690-6-4-NC-VH-xx-xx | 6 | 4.21 | 6.10 | 1.610 | 7.36 | 1.943 | 690 |

| LMxR2-xx-00509-0605-6-4-NC-VH-xx-xx | 6 | 5.09 | 7.38 | 1.948 | 8.90 | 2.351 | 605 |

| LMxR2-xx-00606-0510-6-4-NC-VH-xx-xx | 6 | 6.06 | 8.78 | 2.318 | 10.60 | 2.798 | 510 |

| LMxR2-xx-00711-0430-6-4-NC-VH-xx-xx | 6 | 7.11 | 10.31 | 2.721 | 12.44 | 3.283 | 430 |

| LMxR2-xx-00824-0370-6-4-NC-VH-xx-xx | 6 | 8.24 | 11.95 | 3.155 | 14.42 | 3.808 | 370 |

| LMxR2-xx-01010-0305-6-4-NC-VH-xx-xx | 6 | 10.10 | 14.65 | 3.868 | 17.68 | 4.668 | 305 |